Blog title inspired by the children’s book, The 500 Hats of Bartholomew Cubbins by Dr. Seuss. But please don’t read too much of the book into this blog post title. In fact, it’s better if you stop at just the title, and consider “500 Hats” as analogy for the many tasks of just about any small business owner. To name just a few:

Accountant, farmer, tax preparer, seedsman, customer service representative, seed packager, email and telephone operator, seed extractor, inventory manager, harvester, order processor, acquisitions manager, data entry specialist, food taster, data analyst, photographer, maintenance, trouble-shooter, deliveryman, nurseryman, researcher, production manager, etc.

500 questions like this could be asked, all of them without a simple answer:

“While I am typing my response to an email, who will extract seeds from the 1,000+ lbs. of rotting melons in the cellar?”

At least 20 alternate titles were considered for this blog post:

Internship/Apprenticeship/Replacement

Atomic Habits

3:00 A.M.

Multiplicity

Liminal

Perpetual Triage

Paralysis

Domino Effect and Time

Transition into?

Stressors and Struggles

Dopamine Addiction

Quality vs. Quantity

Sunk Cost Fallacy

A “Real Job”?

ROI by Variety

Sleep Study Results

DT’s FAQ’s

Martyr Complex

Groundhog Day: October 14, 2023

100 Was NOT the Goal

Dandarabilla

Maybe, hopefully, I will get a chance to expand upon each of these over the next few days and weeks. Regrettably, I am too exhausted at the moment to get anywhere close to completing the writing for this post. So far behind on so many tasks, including planting.

The clock waits for no person, now matter how far behind they are. And no amount of will power can surmount extreme fatigue.

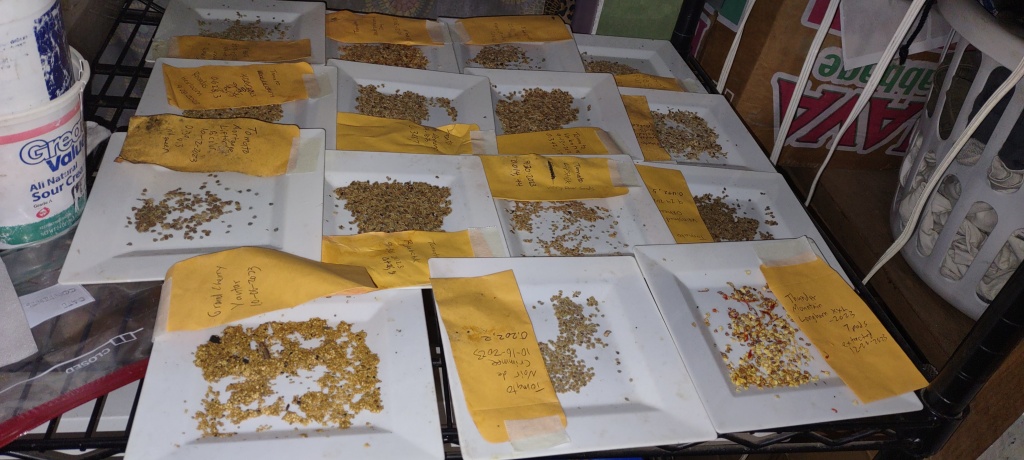

I am very grateful for all the amazing support for the work i have been doing with saving seeds and making them available to other growers around the world! Getting seeds mailed out promptly has been my highest priority every day this month, and required almost every waking minute of my time and challenged my efforts to increase efficiency.

Photos above show nearly 500 packets for about 60 seed requests that came in over the last two weeks of March.

Following is the approximate time budget for those two weeks:

42 Hours: Preliminary work (organizing, printing, data management, planning) took around

65 Hours: Administrative (responding to emails, preparing invoices, etc.)

146 Hours: Label preparation

15 Hours: Seed Packaging

63 Hours: Sleep (sort of – more on that later)

15 Hours: Personal

I work as fast as I can in virtually every waking moment. Where can a cut back? I’m trying to develop a mindset of small, 1% improvement, on processing efficiency at each step: Atomic Habits (the book) approach. Quality vs. Quantity – or is it even possible to have both?